16-2000mm PE umbhobho extrusion line

Isicelo

Iplastiki yombhobho we-HDPE isetyenziselwa ukuvelisa zonke iintlobo zemibhobho ye-HDPE, njenge: unikezelo lwamanzi ezolimo kunye nenkqubo yokukhupha umbhobho, unikezelo lwamanzi olwakhiwo kunye nenkqubo yokukhupha imibhobho, inkqubo yokubonelela ngegesi, njl.

Imibhobho yoxinzelelo

Imibhobho yokubonelela ngamanzi kunye nokuthutha

Ukuhanjiswa kwegesi kunye nemibhobho yokuthutha

Imibhobho yasendle

Imibhobho yokunkcenkceshela yezolimo

Umbhobho wokukhupha wemichiza kunye nokutya

Imibhobho yokukhusela kunye ne-conduit yeentambo zombane kunye neengcingo zonxibelelwano

Imibhobho ye-Fishpond edge guardrail

Inkcazo

Umatshini wombhobho we-hdpe ubandakanya umatshini we-hdpe we-extruder, umbhobho uyafa, iiyunithi zokulinganisa, itanki yokupholisa, ukuthuthwa, isisiki, isitaki/ikhoyila kunye nazo zonke iiperipherals.

Umbhobho weplastiki we-Hdpe umgca we-extrusion uvelisa imibhobho enobubanzi ukusuka kwi-20 ukuya kwi-1600mm kwizinto ezahlukeneyo, ezifana ne-HDPE, i-PP-H njl njl.

Umatshini wombhobho we-Hdpe ukhethwa kwi-ductwork system yegesi, umbhobho wamanzi kunye nombhobho wokunkcenkceshela wezolimo phakathi kwesixeko kunye nelali.

Umbhobho Vacuum Tankflow itshati of Hdpe Umbhobho Extrusion Line

Imathiriyeli ekrwada + isongezo → ukuxuba → umatshini wokutyisa uvacuum → umatshini wokucoca ihopper → isikrufu esinye → isikrazu sebhanti yombala → ukungunda kunye nesilinganisi → umatshini wokulinganisa uvacuum → itanki yokupholisa → umatshini wokutsala → umatshini wokusika → isitaki (Umatshini womoya)

Iimpawu kunye nezinto eziluncedo

1. Umatshini wokwenza umbhobho we-PE uphuhliswa yi-Polestar esekelwe kwi-teknoloji ephezulu yaseYurophu kunye namava e-R & D yoomatshini beplastiki iminyaka emininzi, uyilo oluphambili, isakhiwo esifanelekileyo, ukuthembeka okuphezulu, i-automation ephezulu yomgca wokuvelisa umbhobho we-hdpe.

2. I-Extruder enesakhiwo esikhethekileyo sokutyisa umgqomo unokuphucula kakhulu umthamo wokukhupha.

3. Ulawulo oluchanekileyo oluchanekileyo, iplastiki efanelekileyo, ukusebenza okuzinzileyo.

4. Umgca wokuvelisa umbhobho we-PE wamkela inkqubo yokulawula i-PLC, ukuqonda ukuvumelanisa kunye nokuzenzekelayo.

5. I-Human-computer interface kulula ukuyisebenzisa, iluncedo kwaye inokuthenjwa.

6. Uhlobo lwebhaskithi yeSpiral kunye neletiyisi iyafa ngokuzikhethela.

7. Ukutshintsha ezinye iindawo zomgca nazo zinokuqonda i-two-layer kunye ne-multi-layer co-extrusion.

8. Ukutshintsha ezinye iindawo zomgca kunokuvelisa iPP, iipayipi zePB.

Idatha yoBugcisa

| Umzekelo | Uluhlu lwemibhobho (mm) | Extruder | Die Head | Amandla onke (kW) | Umthamo wemveliso (kg/h) |

| PE-63 | 16-63 | SJ65 | Indawo enye | 100 | 80-120 |

| PE-110 | 20-110 | SJ65 | Indawo enye | 150 | 150-250 |

| PE-160 | 50-160 | SJ75 | Indawo enye | 180 | 150-250 |

| PE-250 | 75-250 | SJ75 | Indawo enye | 230 | 250-350 |

| PE-450 | 160-450 | SJ90 | Indawo enye | 380 | 350-450 |

| PE-630 | 250-630 | SJ120 | Indawo enye | 550 | 700-800 |

| PE-800 | 500-800 | SJ150 | Indawo enye | 800 | 900-1100 |

| PE-1200 | 710-1200 | SJ150 | Indawo enye | 1000 | 1000-1300 |

| PE-1600 | 1000-1600 | SJ150 | Indawo enye | 1200 | 1200-1500 |

Isikruru esiNye Extruder

Ngokusekelwe ku-33: 1 umlinganiselo we-L / D we-screw design, siye saphuhlisa umlinganiselo we-38: 1 L / D. Xa kuthelekiswa ne-33: umlinganiselo we-1, umlinganiselo we-38: 1 unenzuzo ye-100% yeplastiki, ukwandisa umthamo wemveliso nge-30%, ukunciphisa ukusetyenziswa kwamandla ukuya kuma-30% kwaye ufikelele ekusebenzeni kwe-linear extrusion.

I-Simens Touch Screen kunye ne-PLC

Faka isicelo kwinkqubo ephuhliswe yinkampani yethu, ube nesiNgesi okanye ezinye iilwimi ukuba zibe negalelo kwinkqubo.

Ukwakhiwa kwe-Spiral ye-Barel

Ukondla inxalenye yomgqomo wokusetyenziswa kwesakhiwo esijikelezayo, ukuqinisekisa ukutya kwezinto eziphathekayo ngokuzinzileyo kunye nokwandisa umthamo wokutyisa.

Uyilo olukhethekileyo lweScrew

I-Screw yenzelwe kunye nesakhiwo esikhethekileyo, ukuqinisekisa iplastiki efanelekileyo kunye nokuxuba. Izinto ezinganyibilikiyo azikwazi ukudlula le ndawo yesikrufu.

Isifudumezi seCeramic esipholileyo soMoya

Isifudumezi seCeramic siqinisekisa ubomi obude bokusebenza. Olu yilo kukwandisa indawo apho ukudibana kweheater nomoya. Ukuba nesiphumo esingcono sokupholisa umoya.

Umgangatho ophezulu weGearbox

Ukuchaneka kwegiya kufuneka kuqinisekiswe ibanga le-5-6 kunye nengxolo esezantsi engaphantsi kwe-75dB. Ulwakhiwo olubambeneyo kodwa olunetorque ephezulu.

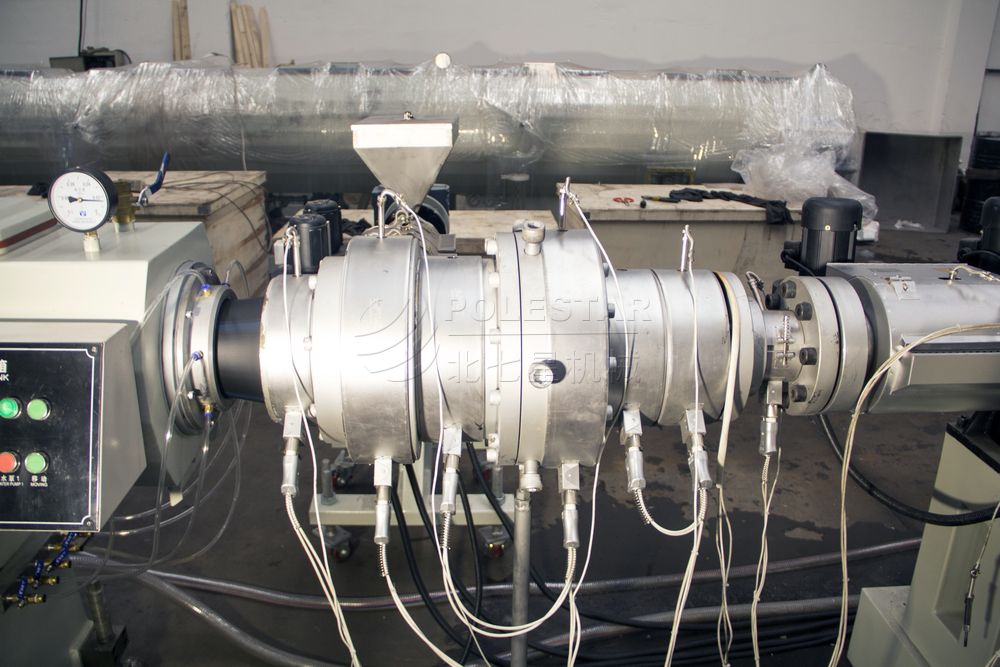

Extrusion Die Head

Intloko yokufa ye-Extrusion ifake i-spiral structure, ijelo ngalinye lokuhamba kwezinto libekwe ngokulinganayo. Ijelo ngalinye lisemva konyango lobushushu kunye nokupolisha kwesibuko ukuqinisekisa ukuhamba kakuhle kwezinto. Die isakhiwo intloko compact kwaye kwakhona ukunika uxinzelelo oluzinzileyo, rhoqo ukusuka 19 ukuya 20Mpa. Ngaphantsi kolu xinzelelo, umgangatho wombhobho ulungile kwaye umphumo omncinci kakhulu kumthamo wokuphuma. Inokuvelisa umaleko omnye okanye umbhobho onemigangatho emininzi.

Isixhobo esishukumayo se-Die Head

Kwintloko enkulu yokufa, isixhobo esishukumayo sinokuhambisa intloko yokufa phambili nasemva, kunye nokulungelelanisa ukuphakama kwentloko yokufa. Ukusebenza kuyakhawuleza kwaye kulula.

Die Head Isixhobo Rotary

Kwintloko enkulu yokufa ngesixhobo esijikelezayo, intloko yokufa inokujikeleza nge-90 degree. Xa utshintsha ityholo, mandrel, die intloko iya kujika 90 degree. Unokusebenzisa i-crane ukuphakamisa kunye nokutshintsha i-bush kunye ne-mandrel. Le ndlela ilula kakhulu.

Isixhobo Sokukhupha Ubushushu

Esi sixhobo songezwa kwintloko yokufa ukuvelisa umbhobho omkhulu kunye nobunzima. Ukuphelisa ubushushu ngaphakathi kombhobho kunye nombhobho wokupholisa ngaphakathi kodonga. Ukuphela kobushushu kungasetyenziselwa ukomisa izinto ezikrwada.

Isixhobo sokupholisa se-Core

Xa ukuvelisa umbhobho ubukhulu obukhulu kunye nobukhulu bodonga, siya kusebenzisa amanzi okupholisa okanye i-oyile kunye nefeni yokupholisa ukupholisa umbindi wentloko yokufa ukuphepha ukufudumeza nokuqinisekisa umgangatho omhle wezinto eziphathekayo.

Itanki yokufunxa

Itanki yokufunxa isetyenziselwa ukumila kunye nokupholisa umbhobho, ukuze ufikelele kubungakanani bombhobho oqhelekileyo. Sisebenzisa isakhiwo segumbi eliphindwe kabini. Igumbi lokuqala linobude obufutshane, ukuqinisekisa ukupholisa okunamandla kunye nomsebenzi wokufunxa. Njengoko i-calibrator ibekwe phambi kwegumbi lokuqala kunye nokumila kombhobho kwenziwa ikakhulu yi-calibrator, olu luyilo lunokuqinisekisa ukubunjwa ngokukhawuleza kunye nokungcono kunye nokupholisa umbhobho.

Ukupholisa okunamandla kwiKhalibrator

Ngenkqubo yokupholisa ekhethekileyo ye-calibrator, enokuba nefuthe elingcono lokupholisa umbhobho kunye nokuqinisekisa isantya esiphezulu. Kananjalo nomgangatho olungileyo womlomo wokutshiza ukuze ube nesiphumo esingcono sokupholisa kwaye akukho lula ukuvaleka bubumdaka.

Inkxaso engcono kwiPipe

Kwimibhobho yobungakanani obukhulu, isayizi nganye inepleyiti yayo yokuxhasa isemicircular. Esi sakhiwo sinokugcina ukujikeleza kombhobho kakuhle kakhulu.

Isithulisi

Sibeka isithulisi kwivalve yokulungelelanisa ukunciphisa ingxolo xa umoya ungena kwitanki yokufunxa.

Ivalve yoNcedo loxinzelelo

Ukukhusela itanki yokufunxa. Xa idigri yevacuum ifikelela kumda omkhulu, ivalve iya kuzivula ngokuzenzekelayo ukunciphisa idigri yevacuum ukunqanda ukophuka kwetanki. Ukunciphisa isidanga seVacuum kunokulungiswa.

Umbhobho weLuphu ephindwe kabini

Ilophu nganye enenkqubo yokucoca amanzi, ukubonelela ngamanzi okupholisa acocekileyo ngaphakathi kwetanki. I-loop ephindwe kabini ikwaqinisekisa ukubonelela ngokuqhubekayo kwamanzi okupholisa ngaphakathi kwetanki.

Amanzi, Isahluli segesi

Ukwahlula amanzi erhasi amanzi. Irhasi iphelile ukusuka phezulu. Amanzi aqukuqela kwicala elisezantsi.

Ulawulo olupheleleyo lwaManzi oluzenzekelayo

Ngokulawulwa kobushushu bomatshini ukuba nolawulo oluchanekileyo noluzinzileyo lobushushu bamanzi.

Ukungena kwamanzi apheleleyo kunye nenkqubo yokuphuma ilawulwa ngokuzenzekelayo, izinzile kwaye ithembekile.

Isixhobo esiseMbindini woMbhobho

Wonke umjelo wamanzi ophuma kwitanki yokufunxa udityanisiwe kwaye uqhagamshelwe kumbhobho omnye ongenastainless. Qhagamshela kuphela umbhobho odibeneyo kumbhobho wangaphandle, ukwenza umsebenzi ube lula kwaye ukhawuleze.

ITanki yokupholisa

Itanki yokupholisa isetyenziselwa ukupholisa umbhobho ngakumbi.

Isixhobo sokuBamba uMbhobho

Esi sixhobo sinokulungelelanisa ukujikeleza kombhobho xa umbhobho uphuma kwi-tank vacuum.

Isihluzo seTanki yamanzi

Ngecebo lokucoca kwitanki yamanzi, ukuthintela nakuphi na ukungcola okukhulu xa amanzi angaphandle engena.

Umgangatho wokutshiza uMlomo

Imilomo yokutshiza esemgangathweni inesiphumo esingcono sokupholisa kwaye akukho lula ukuvaleka bubumdaka.

Isixhobo soLungiso lweNkxaso yombhobho

Inkxaso kunye nomsebenzi wokulungelelanisa ukuxhasa umbhobho kunye nobubanzi obuhlukeneyo.

Isixhobo seNkxaso yePipe

Isetyenziswa ngakumbi xa kuveliswa umbhobho onobubanzi obukhulu kunye nobukhulu bodonga. Esi sixhobo siya kunika inkxaso eyongezelelweyo kwimibhobho enzima.

Haul Off Unit

Iyunithi yokukhupha inika amandla awoneleyo okutsala ukutsala umbhobho ngokuzinzileyo. Ngokobungakanani bombhobho obahlukeneyo kunye nobukhulu, inkampani yethu iya kwenza ngokwezifiso isantya sokutsala, inani leenzipho, ubude bokutsala obusebenzayo. Ukuqinisekisa isantya sombhobho womdlalo we-extrusion kunye nesantya sokwenza, kunqande ukuguqulwa kombhobho ngexesha lokutsalwa.

Yahlula i-Traction Motor

Uzipho ngalunye lunemoto yalo yokutsala, ukuba xa enye injini yokutsala iyeka ukusebenza, ezinye iinjini zisenokusebenza. Unokukhetha i-servo motor ukuba ibe namandla amakhulu okutsala, isantya esizinzile ngakumbi kunye noluhlu olubanzi lwesantya sokutsala.

Isixhobo sokuLungisa uzipho

Zonke iinzipho ziqhagamshelwe enye kwenye, xa kulungiswa indawo yeenzipho ukutsala umbhobho ngobungakanani obahlukeneyo, zonke iinzipho ziya kuhamba kunye. Oku kuya kwenza ukuba umsebenzi ukhawuleze kwaye ube lula.

Uyilo oluLungelelekileyo lomsebenzisi

Nge-Siemens hardware kunye nesoftware esebenzisekayo eyilwe yinkampani yethu. Yiba nomsebenzi olungelelanisiweyo kunye ne-extruder, yenza umsebenzi ube lula kwaye ukhawuleze. Kwakhona umthengi unokukhetha kuphela ezinye iinzipho ukuba zisebenze ukutsala imibhobho emincinci kakhulu.

Ulawulo loxinzelelo lomoya olwahlukileyo

Uzipho ngalunye olunolawulo lwalo loxinzelelo lomoya, luchaneke ngakumbi, ukusebenza kulula.

Umsiki

I-Cutter elawulwa yi-Siemens PLC, isebenza kunye neyunithi yokukhupha ukuze ibe nokusika okuchanekileyo. Umthengi unokuseta ubude bombhobho abafuna ukuwunqumla. Iintshukumo ezininzi zokondla ukufezekiswa kwenkqubo enye yokusika (ukukhusela iincakuba kunye neesarha, uthintele kwincakuba kunye neesarha ezibambeke kumbhobho oshinyeneyo kunye nobuso obusikiweyo bombhobho bugudileyo).

Isixhobo sokuChwetheza seHlabathi liphela

Faka isixhobo sokucinezela jikelele kwiisayizi ezahlukeneyo zemibhobho, akukho mfuneko yokutshintsha isixhobo sokubamba xa ubungakanani bombhobho butshintsha.

ISaw kunye neBlade ziyaTshintshwa

Abanye abasiki baxhotyiswe ngeesarha kunye neblade. I-Saw and blade cutting iyatshintsheka kwiisayizi ezahlukeneyo zemibhobho. Kwakhona, isarha kunye nencakuba zinokusebenzisana kwimfuno ekhethekileyo.

Uhlengahlengiso loMphakamo ophakathi

Ngesixhobo sokulungelelanisa sombane kwisixhobo sokubambelela. Ukusebenza ngokukhawuleza kwaye kulula. Ngokutshintsha umda ukuqinisekisa ukhuseleko.

Stacker

Ukuxhasa kunye nokothula imibhobho. Ubude be-stacker bunokwenziwa ngokwezifiso.

Ukukhuselwa komphezulu wombhobho

Nge-roller, ukukhusela umbhobho wombhobho xa uhambisa umbhobho.

Uhlengahlengiso loMphakamo ophakathi

Ngesixhobo esilula sokulungelelanisa ukulungelelanisa ukuphakama okuphakathi kwiisayizi ezahlukeneyo zepayipi.

Ikhoyili

Ukudibanisa umbhobho kwi-roller, kulula ukuyigcina kunye nokuthutha. Ngokuqhelekileyo isetyenziselwa umbhobho ongaphantsi kobukhulu be-160mm. Yiba nesikhululo esinye kunye nesikhululo esiphindwe kabini sokuzikhethela.

Ukusetyenziswa kwe-servo motor

Unokukhetha i-servo motor yokususwa kombhobho kunye nokujika, ichaneke ngakumbi kunye nokuhamba kombhobho okungcono.

Iindidi zeemveliso

Ngaba uyafuna ukongeza isibhakabhaka kuyilo lwakho?

Qhagamshelana nathi namhlanje ukudibana noyilo.