EJamani iTekhnoloji yePlastiki yePlastiki ye-PE PP yoMshini wokuNxibelela

Iinkcukacha

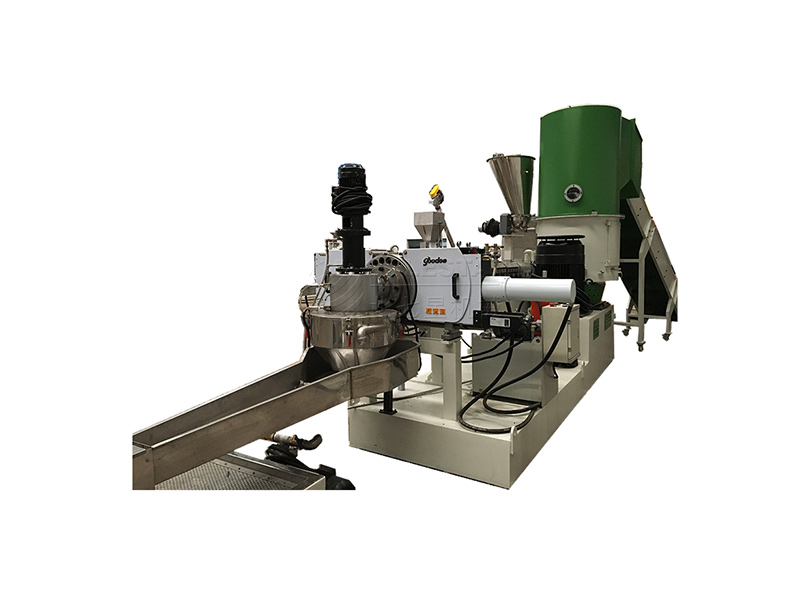

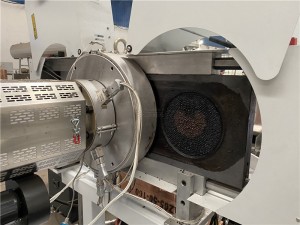

Umatshini we-POLESTAR weplastiki yeplastiki / iiGranulator zePlastiki ezibonelela ngokusasazwa kokufudumeza okufanayo kunye ne-homogenization ilungele ukuvelisa iipellet zeplastiki kwinkqubo yokubuyisela kwakhona. Umatshini wePlastiki we-pelletizer uyafumaneka kwi-single (umatshini omnye we-extrusion kuphela) kunye nolungiselelo lwenqanaba eliphindwe kabini (umatshini omnye ophambili kunye nomatshini omncinci omncinci wesibini we-extrusion). Kucetyiswa ukuba kusetyenziswe ulungelelwaniso lwenqanaba eliphindwe kabini kwinkqubo yokuphinda isetyenziswe ngenxa yokungcoliswa kwezinto zeplastiki. Kukwakho iindlela ezahlukeneyo zokhetho lwetekhnoloji yeplastiki yegranule pelletizing efumanekayo njengokutshintsha kwesikrini esincediswa yihydraulic kunye nepiston ephindwe kabini yokutshintsha isikrini ukuqinisekisa ukuba akukho siphazamiso ngexesha lokutshintsha kwesikrini. Ibhokisi yethu yegiya ethembekileyo iqhuba ngokuzolileyo ukuze ixube kwaye ihambise iplastiki etyhidiweyo emgqomeni. Isikrufu esenziwe ngentsimbi ephathwe ngokukodwa siqinisekisa ngokuchasene nokubola kunye nokulimala. Inkqubo yokulawula ubushushu be-PID enomoya okanye inkqubo yokupholisa amanzi igcina ubushushu bokusebenza obuzinzileyo. "I-Hot Cut" i-water-ring die face pelletizing kunye ne "Cold Cut" iindlela ze-strand pelletizing ziyafumaneka ngokuxhomekeke kukhetho lwakho.

Isicelo

Imathiriyeli ekrwada: PE, PP Iifilimu kunye neengxowa

Umatshini wegranulator yePlasitiki / umatshini weplastiki wepelletizer / umatshini weplastiki wepelletizer oneagglomerator unokusetyenziselwa ifilimu ye-PE / PP okanye iingxowa ezilukiweyo zePP kunye ne-parabolic pellet yokuphinda isetyenziswe, izixhobo ziya kucinezelwa ngakumbi ngokudibanisa okuya kuba lula ukuphoswa ukukhupha ngaphandle, enokufezekisa umthamo omkhulu we-100-100kg / iyure (kuxhomekeke kwiimfuno zabathengi)

Ithuba elihle lokhuphiswano

1. Inqanaba eliphezulu le-automation, zama kangangoko ukunciphisa iindleko zakho emsebenzini kwaye uqinisekise umthamo ophezulu wokucubungula.

2. Inkqubo yokulawula ubuhlobo (i-PLC edibeneyo kunye nolawulo oluhlukeneyo kumatshini ngamnye) kunye nepaneli yesikrini seTouch, kulula ukusebenza, ukubeka iliso kunye nokuyeka ngokukhawuleza.

3. Zonke iindawo ezinxibelelana nezinto zeplastiki kunye namanzi zenziwe nge-stainless steel 304 ephezulu; Qinisekisa ukuba akukho ngcoliseko lwesibini kwiiflakes.

4. Siemens contactor, RKC isilawuli lobushushu

Iimpawu eziphambili

1. Ulawulo oluzenzekelayo kakhulu, olusebenziseka lula, olusebenza kakuhle kakhulu, ukhuseleko lokusingqongileyo kunye nokonga amandla;

2. Iindlela ezahlukeneyo zepelletizing, ezinje ngentambo ebandayo, i-water-ring, kunye nangaphantsi kwamanzi kwizinto ezahlukeneyo ezikrwada kunye neemfuno zemveliso;

3. Izitishi ezininzi zokutshintsha isikrini kunye noyilo oluzenzekelayo lokutshintsha isikrini kunokunciphisa umsebenzi wezandla kunye nokuphucula ukusebenza lula;

4. Isigaba esisodwa kunye nesibini, i-multi-exhaust kunye nenkqubo yokucoca iqinisekisa umgangatho ophezulu kunye neemveliso;

5. Ilungele ukusetyenzwa kwezinto ezahlukeneyo, nayo inokuyila ngokukodwa umatshini wesixhobo esinye okanye izinto ezahlukeneyo, ezinokunciphisa iindleko zotyalo-mali lwabathengi.

Idatha yoBugcisa

Inqanaba elinye lomgca we-agglomeration granulation

| Umzekelo | 70 | 100 | 120 | 150 | 180 |

| Imveliso (kg/h) | 70-120 | 200-250 | 300-400 | 500-600 | 700-850 |

| Ukusetyenziswa kwamandla (kWh/kg) | 700-850 | ||||

| Amandla angundoqo (kW) | 37 | 90 | 110 | 132 | 185 |

| Amandla eAgglomerator(kW) | 30 | 55 | 75 | 110 | 132 |

| Isikrufu sangaphandle sedayamitha (L/D) | 70(33:1) | 100(30-35:1) | 100(30-35:1) | 100(30-35:1) | 180(30-32:1) |

| Vacuum exhauum | Ukhetho | ||||

| Umtshintshi wesikrini | Ubumbeko olusemgangathweni | ||||

| Amanzi-ring granulation | Ukhetho | ||||

| Igranulation yomcu obandayo | Ukhetho | ||||

| Igranulation engaphantsi kwamanzi | Ukhetho | ||||

Inqanaba eliphindwe kabini leagglomeration line granulation

| Umzekelo | 70+90 | 100+120 | 120+150 | 150+180 | 180+200 |

| Imveliso (kg/h) | 110-180 | 200-300 | 300-450 | 500-650 | 700-850 |

| Ukusetyenziswa kwamandla (kWh/kg) | 0.2-0.35 | ||||

| Amandla angundoqo (kW) | 30+22 | 75+37 | 90+45 | 110+55 | 160+75 |

| Amandla eAgglomerator(kW) | 30 | 55 | 75 | 110 | 132 |

| Isikrufu sangaphandle sedayamitha(L/D) | 70(25+12:1) | 100(25+12:1) | 120(25+12:1) | 150(25+12:1) | 180(25+12:1) |

| Vacuum exhauum | Ukhetho | ||||

| Umtshintshi wesikrini | Iiseti ezi-2 zokumisela umgangatho | ||||

| Amanzi-ring granulation | Ukhetho | ||||

| Igranulation yomcu obandayo | Ukhetho | ||||

| Igranulation engaphantsi kwamanzi | Ukhetho | ||||

Iindidi zeemveliso

Ngaba uyafuna ukongeza isibhakabhaka kuyilo lwakho?

Qhagamshelana nathi namhlanje ukudibana noyilo.