SJZ Series Conical Twin Screw Extruder

Iimpawu

I-SJZ series conical twin screw extruder ikwabizwa ngokuba yi-PVC extruder ineenzuzo ezinjengokukhupha ngenkani, umgangatho ophezulu, ukuguquguquka okubanzi, ubomi obude bokusebenza, isantya esisezantsi sokucheba, ukubola kanzima, ukudityaniswa okuhle kunye nesiphumo seplastiki, kunye nokubunjwa ngokuthe ngqo kwemathiriyeli yomgubo kunye njl. iiyunithi processing iqinisekisa iinkqubo ezizinzileyo kunye nemveliso ethembekileyo kakhulu kwizicelo ezininzi ezahlukeneyo. Umatshini we-twin screw extruder unemveliso ephezulu, uhlala ubalaseleyo umgangatho wemveliso kunye nomlinganiselo obalaseleyo wokusebenza-phezu kwalo lonke uluhlu lokusebenza.

Lo matshini we-pvc conical twin screw extruder, umatshini we-pvc we-extruder ulungele ukuhambelana nomgca wokuvelisa wepayipi yeplastiki, ipleyiti kunye neprofayili kunye nokunye.

Sikwavelisa ezinye iiplastic extruder ezifana neplastic single screw extruder, 120mm single screw extruder, pvc extruders, plastic pellet extruder,pp extruder, extruder plastic recycled, extruder encinci, lab plastic extruder njalo njalo.

Iingenelo

1.Ifumaneka kwi-PVC eqinile kunye nethambileyo iquka i-C-PVC

I-2.Uyilo olulodwa lwe-screw ukuphumeza iplastiki ephezulu kunye nomgangatho weemveliso

3.Core self-circulation lobushushu ubushushu for screw. Inkqubo echanekileyo yokulawula ubushushu

I-4.Ibhokisi ye-Gearbox ephezulu ye-torsion balance ukuze iqonde ukusebenza okuzinzileyo, ukushisa kweoli ephantsi ekhoyo

5.Inkqubo yokujikeleza ngokuzenzekelayo kunye nebonakalayo ye-lubricant kwibhokisi yegiya

6.H isakhelo sokumila ukunciphisa ukungcangcazela

Iphaneli yokusebenza ye-7.PLC yokuqinisekisa ungqamaniso.

8.Ukugcinwa kwamandla, kulula ukuyigcina

Idatha yoBugcisa

| Umzekelo | SJZ51 | SJZ65 | SJZ80 | SJZ92 | SJZ105 |

| Screw DIA(mm) | 51/105 | 65/132 | 80/156 | 92/188 | 105/216 |

| Ubuninzi besikrufu | 2 | 2 | 2 | 2 | 2 |

| Indlela yokukrazula | Ichasa nangaphandle | ||||

| Isantya seScrew(rpm) | 1-32 | 1-34.7 | 1-36.9 | 1-32.9 | 1-32 |

| Ubude beScrew(mm) | 1070 | 1440 | 1800 | 2500 | 3330 |

| Ulwakhiwo | Umnatha weConical | ||||

| Amandla enjini angundoqo(kw) | 18.5 | 37 | 55 | 110 | 185 |

| Amandla ewonke(kw) | 40 | 67 | 90 | 140 | 255 |

| Imveliso(ubuninzi: kg/h) | 120 | 250 | 360 | 800 | 1450 |

| Isiqingatha sommandla wokufudumeza umphanda | 4 | 4 | 4 | 5 | 6 |

| Umondli | Idosi ye-Screw | ||||

| Umphakamo wombindi womatshini(mm) | 1000 | 1000 | 1000 | 1100 | 1300 |

I-Twin Screw Extruder

Zombini i-conical twin screw extruder kunye ne-parallel twin screw extruder ingafakwa ukuvelisa umbhobho wePVC. Ngeteknoloji yakutshanje, ukunciphisa amandla kunye nokuqinisekisa umthamo. Ngokwefomula eyahlukileyo, sibonelela ngoyilo olwahlukileyo lwesijiko ukuqinisekisa isiphumo esihle seplastiki kunye nomthamo ophezulu.

I-Simens Touch Screen kunye ne-PLC

Faka isicelo kwinkqubo ephuhliswe yinkampani yethu, ube nesiNgesi okanye ezinye iilwimi ukuba zibe negalelo kwinkqubo

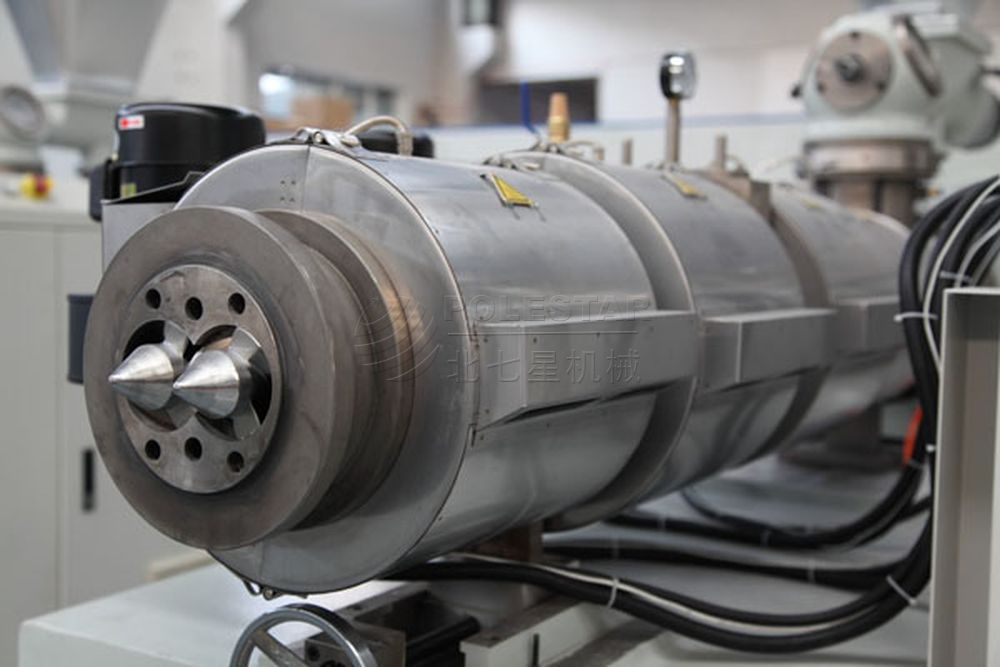

Umgangatho Screw kunye Umphanda

I-Screw kunye ne-barrel zisebenzisa i-high quality alloy steel, eqhutywe yi-CNC ukuqinisekisa umgangatho, ukuchaneka kunye nexesha elide lenkonzo. Izinto zeBimetallic zokhetho.

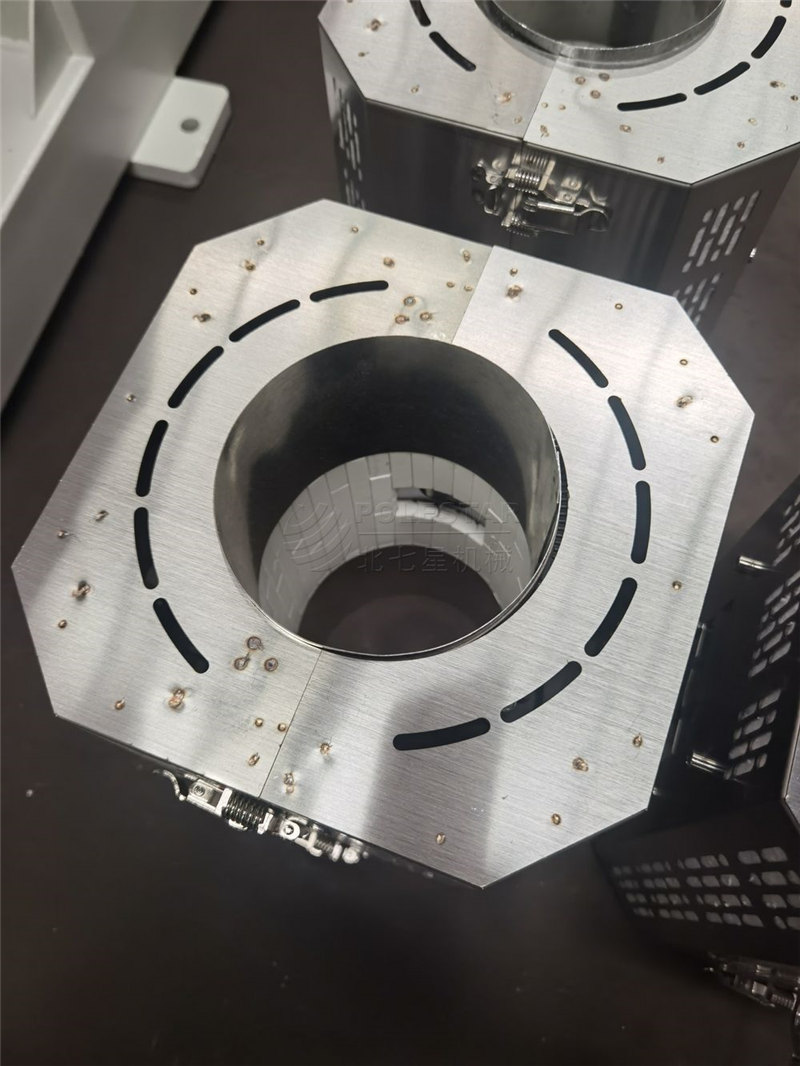

Isifudumezi seCeramic esipholileyo soMoya

Isifudumezi seCeramic siqinisekisa ubomi obude bokusebenza. Olu yilo kukwandisa indawo apho ukudibana kweheater nomoya. Ukuba nesiphumo esingcono sokupholisa umoya.

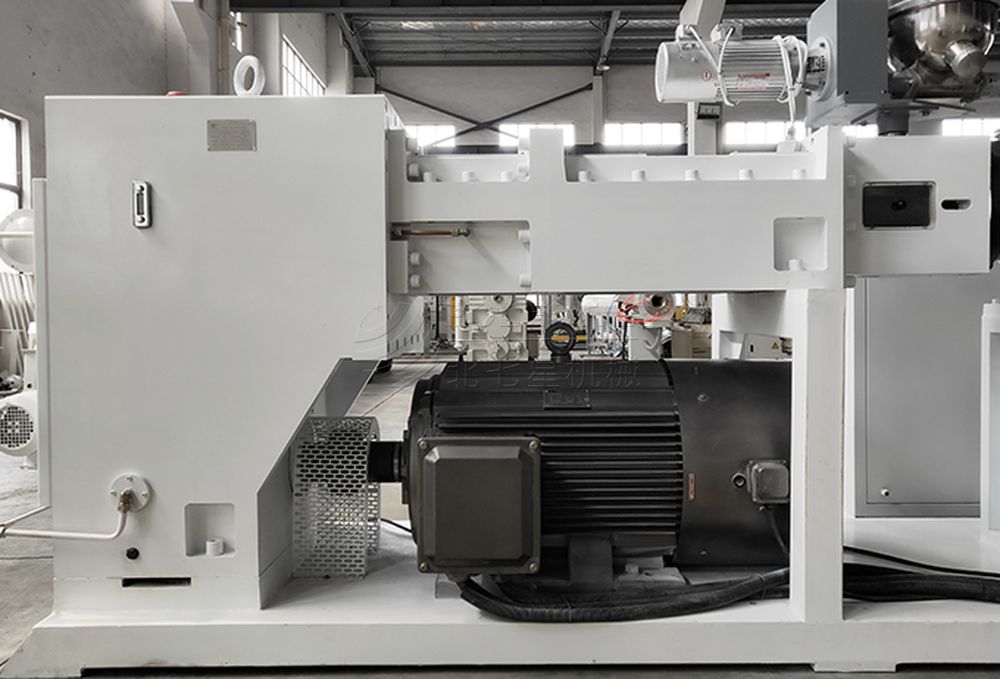

Umgangatho ophezulu weGearbox kunye neBhokisi yoSasazo

Ukuchaneka kwegiya kufuneka kuqinisekiswe ibanga le-5-6 kunye nengxolo esezantsi engaphantsi kwe-75dB. Ulwakhiwo olubambeneyo kodwa olunetorque ephezulu.

Ukupholisa ngcono kwebhokisi yegiya

Ngesixhobo sokupholisa esizimeleyo kunye nempompo yeoli, ukwenza isiphumo esingcono sokupholisa ioyile yokuthambisa ngaphakathi kwibhokisi yegiya.

Inkqubo yeVacuum ekwinqanaba eliphezulu

Inkqubo yokucoca ekrelekrele, gcina idigri yevacuum ngaphakathi koluhlu olumiselweyo. Xa ivacuum ifikelela kumda ophezulu, impompo iya kuyeka ukusebenza ukugcina amandla kwaye iya kusebenza kwakhona xa ivacuum yehla ngaphantsi komda osezantsi.

Easy Cable Connection

Indawo nganye yokufudumeza, ukupholisa kunye nokufumanisa ubushushu inendawo yayo yokudibanisa kwikhabhinethi. Kufuneka nje ukudibanisa iplagi edibeneyo kwisiseko sekhabhinethi, umsebenzi ulula kwaye ulungele.

Iindidi zeemveliso

Ngaba uyafuna ukongeza isibhakabhaka kuyilo lwakho?

Qhagamshelana nathi namhlanje ukudibana noyilo.